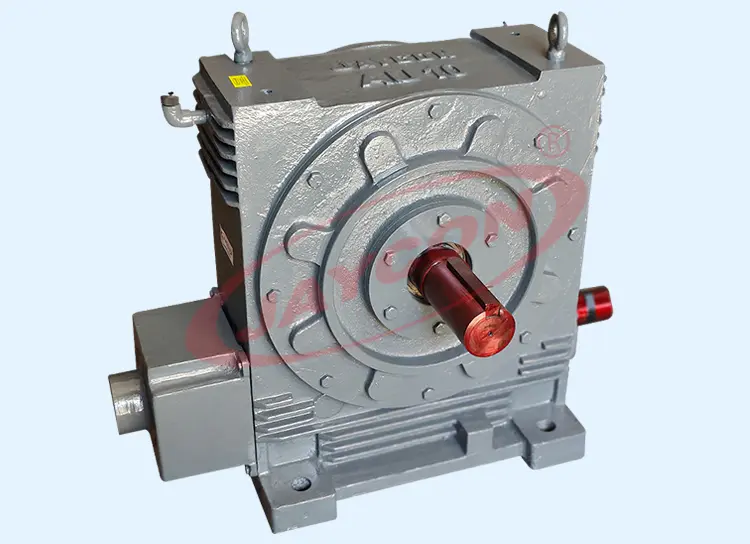

A Horizontal Worm Reduction Gearbox is a type of gearbox that is commonly used in industrial applications to reduce the speed of a motor and increase performance. The worm reduction gearbox is designed to provide a compact and efficient solution for transmitting power from the motor to the driven machine.

The gearbox consists of a worm gear that meshes with a worm wheel, transmitting power from the motor to the driven machine. The gearbox is typically housed in a horizontal configuration, making it ideal for applications where space is limited. The compact design of the gearbox allows for easy installation and maintenance, reducing downtime and improving overall system efficiency.

The capacity of the horizontal worm reduction gearbox to deliver a high degree of torque multiplication with optimal efficiency is one of its primary features. The huge reduction ratio provided by the worm gear design improves the amount of torque that can be delivered from the motor to the machine being driven. The gearbox is therefore the perfect choice for situations that call for high torque and low speed operation. The gearbox is made to transfer power from the motor to the driven machine smoothly and effectively, minimising energy losses and increasing system effectiveness overall. As a result, over the gearbox's lifetime, there may be considerable financial savings.

Reduced Worm Size Horizontally Conveyors, mixers, crushers, and other pieces of machinery requiring high torque and low speed frequently employ gearboxes in a variety of industrial applications. To satisfy the unique requirements of each application, they are offered in a variety of sizes and combinations.

Our range of Horizontal Worm Reduction Gearbox is designed in such a way to decrease the speed by increasing the torque significantly. Worm Reduction elements are developed for heavy load works and power transmission with the latest technology.