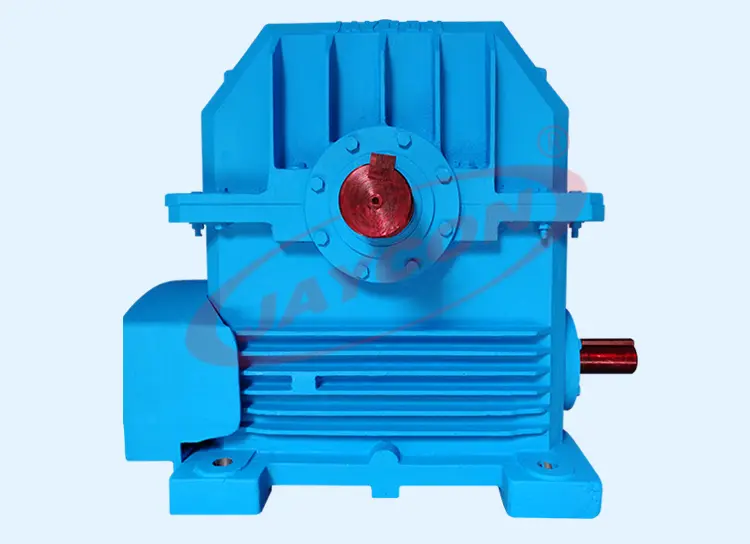

When a motor's speed has to be slowed down and its performance needs to be increased, a worm reduction gear box is applied made from Jaycon Gears. Power is transferred from the motor to the load using a worm gear and worm wheel that performs altogether. A gear called a worm gear is shaped like a screw, and a worm wheel is a cylindrical gear that meshes with a worm gear.

The high reduction ratio and efficiency of a worm reduction gear box are its main features. The worm gear may achieve a large reduction ratio with just one gear stage because of its high helix angle which makes it perfect for use in situations where great torque is required, including in heavy machinery or industrial equipment, as it may decrease the speed of a motor while boosting its efficiency. The contact area between the worm gear and the worm wheel is significantly bigger than with other types of gears due to the sliding movement between the two, which aids in more evenly distributing the load. As a result, the worm gears experience less wear and tear, and the system as a whole performs better.

Worm reduction gearboxes are available in a great range of sizes and capacities, making them suitable for a wide variety of industrial applications. They are mainly used in conveyor systems, packaging machinery, food processing equipment, and other types of industrial machinery. When selecting a worm reduction gear box, it is important to consider primary factors such as the required reduction ratio, the maximum torque and speed, and the overall durability and reliability of the gearbox.

We are manufacturing a range of Worm Reduction Gearbox, which have vast applications in various industries such as Stone Crusher Plants, Road Construction Machinery, Cement Plants, Textile Industries etc.