An SMSR gearbox, often referred to as a shaft mounted speed reducer, is a type of gearbox frequently used in industrial applications to enhance torque while reducing motor speed. The SMSR Gearbox is a small and effective design that attaches directly onto the motor shaft, doing away with the need for a base plate or additional connection.

Through a series of gears, the SMSR Gearbox transfers power from the motor to the driven machine. These gears increase the torque output while reducing the motor's speed. A casing, a set of gears, and bearings to sustain the load make up a gearbox in most cases.

Key advantages of the SMSR Gearbox is its compact design and high efficiency. The gearbox is mounted directly onto the motor shaft, eliminating the need for a separate base plate or coupling. This not only reduces the overall footprint of the system but also makes installation and maintenance easier and more cost-effective.

SMSR Gearboxes are frequently employed in a variety of industrial applications, including as conveyors, crushers, mixers, and other machinery requiring high torque and low speed. For each application's unique requirements, they come in a variety of sizes and combinations like Holdback SMSR Gearbox, Backstop SMSR Gearbox, AntiLock SMSR Gearbox, Anti Reverse SMSR Gearbox and Fenner Type SMSR Gearbox.

We are the pioneer manufacturer of Shaft Mounted Speed Reducer (SMSR) Gearbox and introduced for the first time in the market of Gujarat in the year of 1974. Since then, JAYCON SMSR Gearbox has been the market leader having been used in many industries such as Textile Processing Machinery, Chemical Plants, Mini Cement Plant, Road Construction Plants and Crushing Plants.

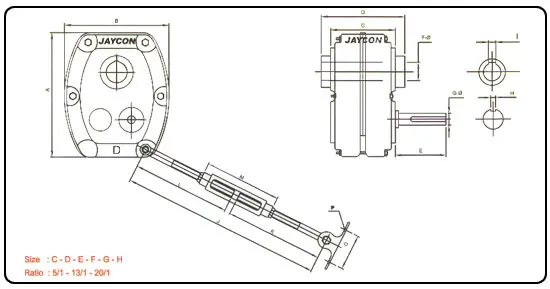

JAYCON SMSR Gearbox are totally enclosed and consist of hardened & precision machined Alloy Steel Gears mounted on highly finished shafts supported on long life Bearings of capacity to take maximum load. Two piece close grain C.I. housing provide sturdy support and insures permanent accurate alignment of all components.

| SIZE | A | B | C | D | E | F-Q | G-Q | H | I | J | K | L | M | O | P | Appro.Kg | Appro.Oil | Suitable For | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 13-20 | 5 | 13-20 | |||||||||||||||||

| C | 275 | 220 | 110 | 147 | 65 | 35 | 22 | 6 X 3 | 10 X 5 | 565 | 270 | 270 | 150 | 75 | 10 | 21 | 25 | 0.6 | 0.5 | 2 HP |

| D | 330 | 245 | 120 | 163 | 75 | 50 | 25 | 9 X 4 | 14 X 5 | 565 | 270 | 270 | 150 | 75 | 10 | 32 | 35 | 1 | 0.8 | 3 Hp |

| E | 382 | 280 | 130 | 171 | 80 | 55 | 28 | 9 X 4 | 16 X 5 | 565 | 270 | 270 | 180 | 75 | 12 | 44 | 50 | 1.9 | 1.7 | 5 HP |

| F | 410 | 315 | 150 | 205 | 90 | 65 | 32 | 10 X 5 | 16 X 5 | 565 | 270 | 270 | 180 | 75 | 12 | 65 | 70 | 2.6 | 2.3 | 7.5 HP |

| G | 490 | 400 | 170 | 220 | 105 | 75 | 42 | 12 X 5 | 20 X 5 | 565 | 270 | 270 | 180 | 75 | 12 | 12 | 91 | 98 | 3 | 10-12.5 HP |

| H | 565 | 450 | 195 | 250 | 116 | 85 | 48 | 14 X 5 | 22 X 8 | 565 | 270 | 270 | 180 | 75 | 12 | 12 | 140 | 150 | 4.5 | 15 Hp |